The history of industry is a journey of constant transformation, and your company is no exception. Have you ever wondered where you are on this path? Are you still operating with methods from the past, or are you about to leap into the factory of the future?

Today, we begin a deep analysis of industrial evolution, from the age of steam to collaborative intelligence. Discover where your company stands and how you can take the next step toward a smarter, more efficient, and, above all, more profitable operation.

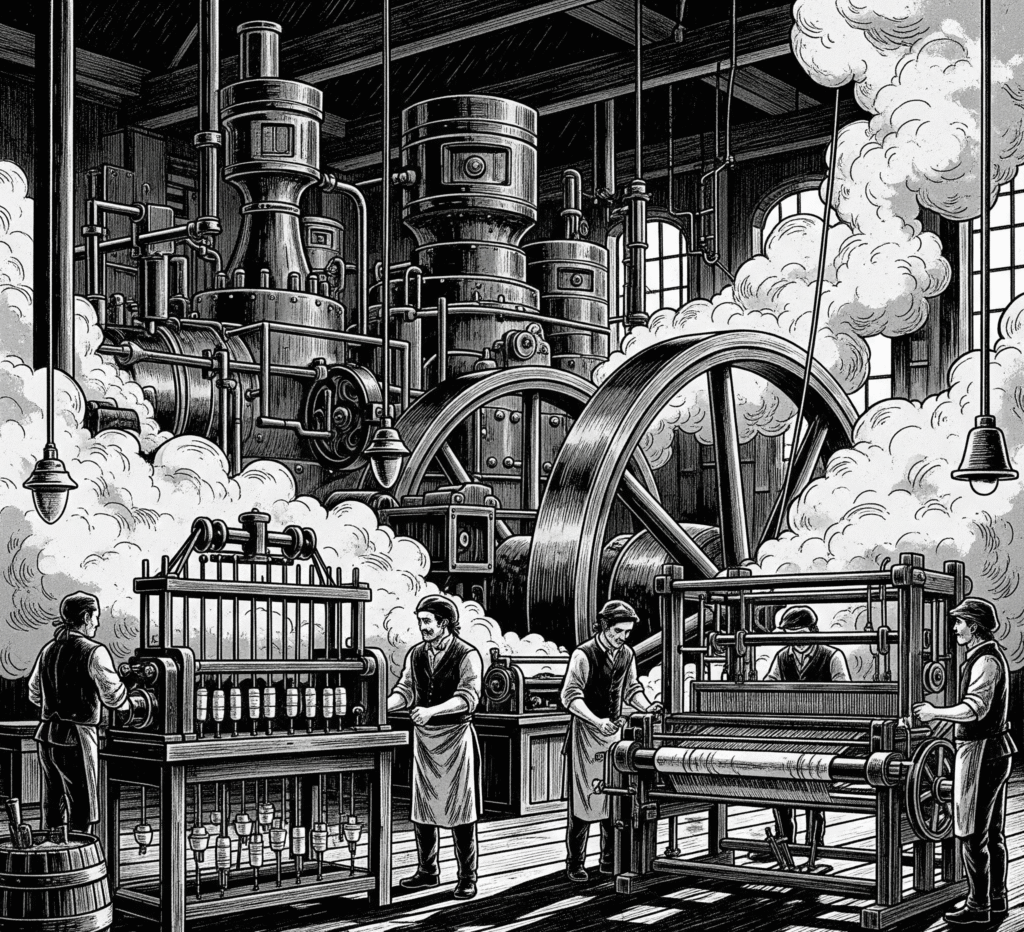

1.0: The Age of Mechanization and the Efficiency Challenge

The journey began with Industry 1.0, the period of mechanization powered by steam and water. This revolution, which started in Great Britain around 1760, replaced manual labor and gave rise to the factory system. With James Watt’s improvements to the steam engine, factories were no longer tied to rivers, allowing them to be established in urban centers with greater access to labor. This era created a new class of “wage laborers” and marked a shift where decisions were often based on intuition rather than concrete data.

However, many companies today still carry the traits of this era:

- Isolated machines that do not share data.

- Total dependence on manual and physical labor.

- Strategic decisions based on intuition, not on concrete data.

If these challenges sound familiar, A+Bizz offers a simple and effective solution to help you evolve.

A+Bizz can guide you to a smarter and more efficient operation. Talk to us and schedule a free demonstration.

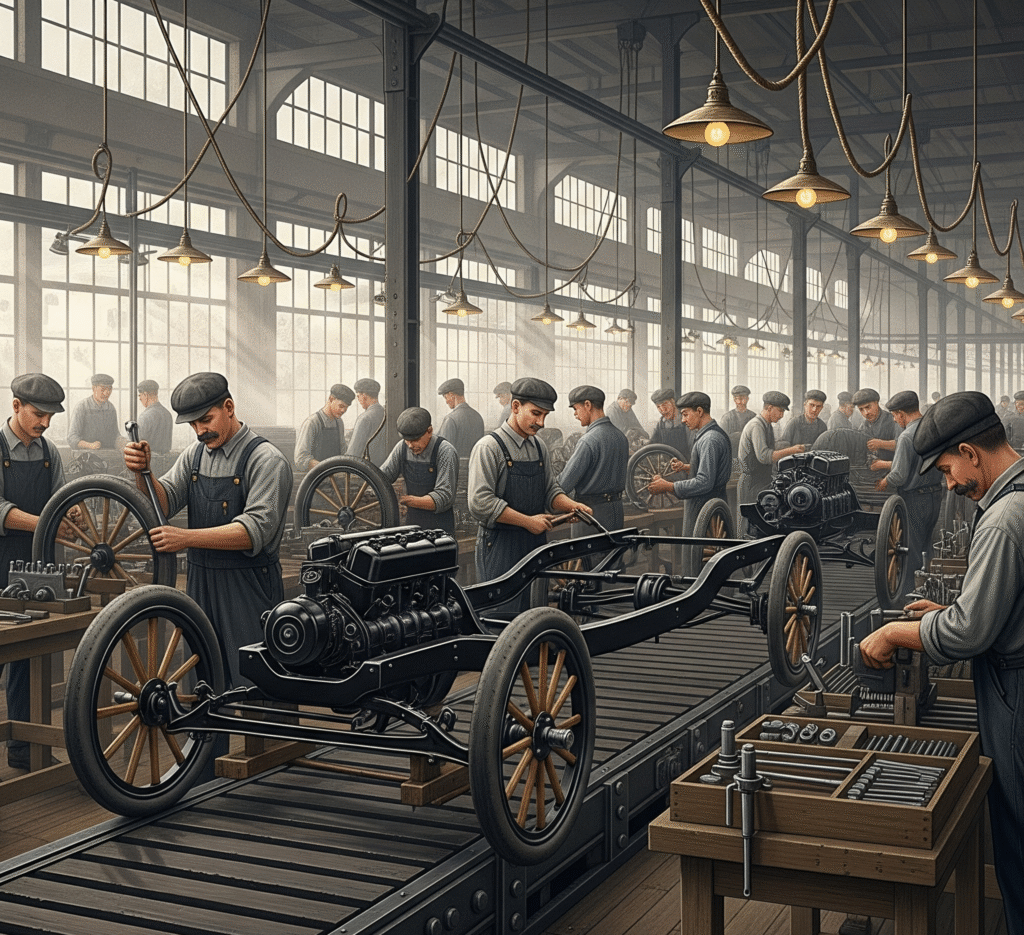

2.0: Mass Production and the Flexibility Dilemma

Industry 2.0, driven by electricity, brought the assembly line and mass production to the forefront. Pioneers like Henry Ford perfected this system, which brought the work to the worker and made once-luxury items like automobiles affordable to a new middle class. This was a phase of high speed and standardization, but with a new set of costs.

Many companies still operate in this logic, facing obstacles such as:

- Rigid and inflexible assembly lines.

- Excessive dependence on labor for repetitive tasks.

- Low ability to adapt to new market demands or product customization.

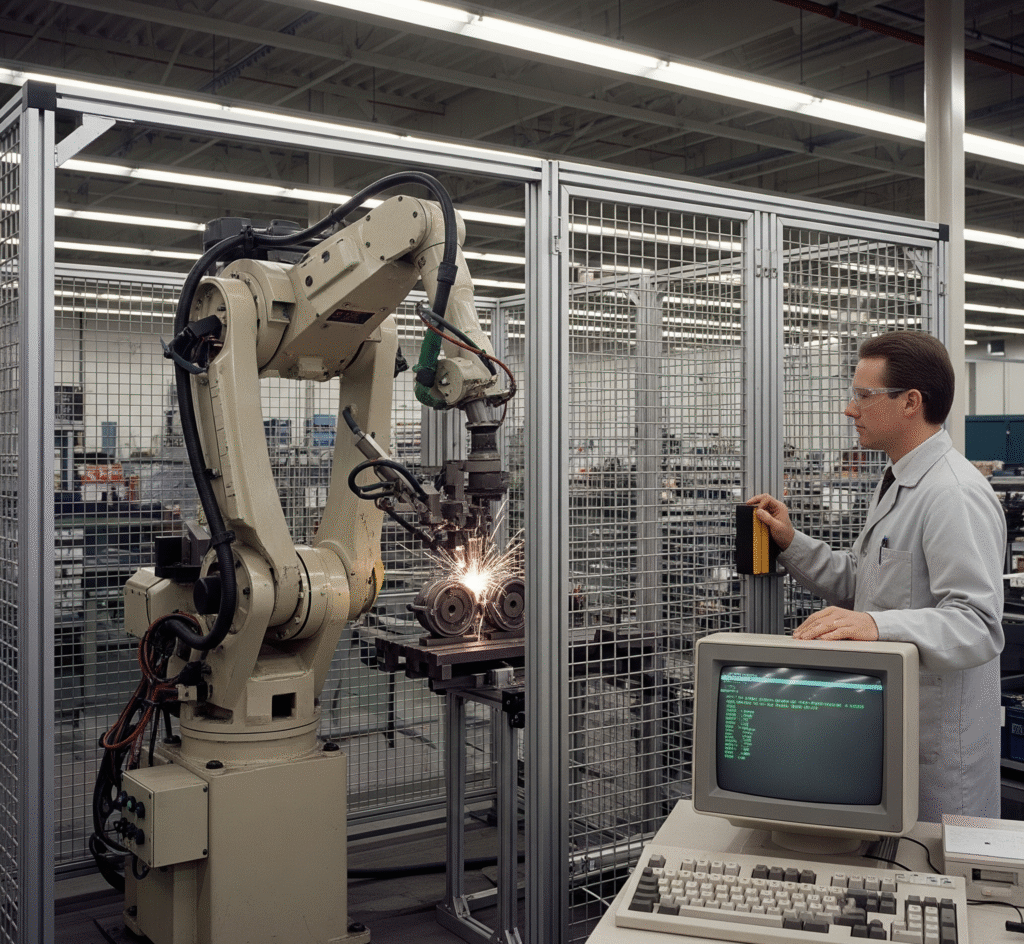

3.0: The Digital Revolution and the Limitation of Isolated Systems

The arrival of computers and electronics in Industry 3.0 introduced automation to the factory floor. Machines began to perform repetitive tasks, freeing workers for supervision and programming. The invention of the microchip and the internet digitized information and control, allowing for “automação rígida” (rigid automation). However, this automation was often fragmented, with systems that couldn’t communicate.

Are you still facing these problems?

- Isolated systems that do not communicate with each other (islands of information).

- Inability to collect and analyze data for quick decision-making.

- Difficulty reconfiguring production without specialized technical intervention.

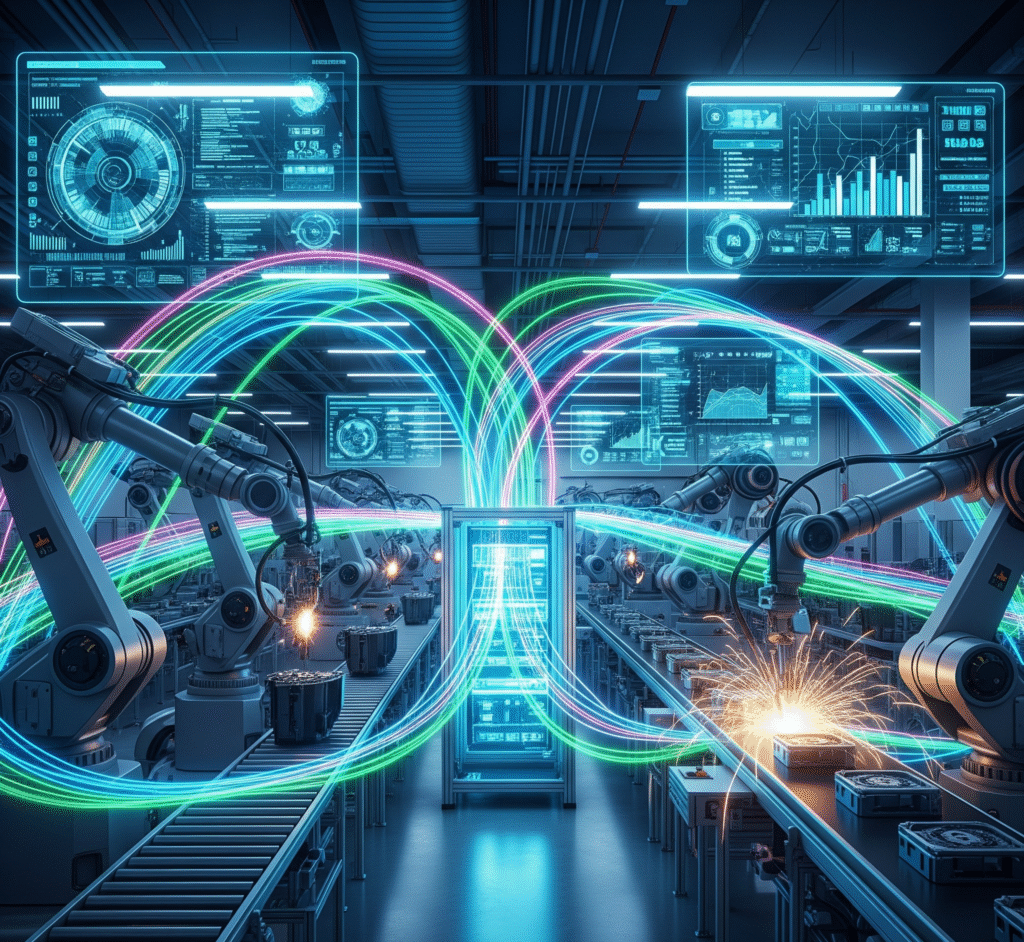

4.0: The Smart Factory and A+Bizz as the Solution

Industry 4.0 is the era of smart factories. The fusion of technologies like IoT (Internet of Things), Big Data, and Artificial Intelligence creates an environment where machines, systems, and people are fully interconnected. Data flows in real time, enabling intelligent automation and faster decisions.

However, even companies that have already made this digital leap may face obstacles, such as the difficulty of integrating dispersed systems and obtaining complete visibility into performance. This is where A+Bizz comes in.

Our platform was created to help SMEs enter the universe of Industry 4.0 in a simple, efficient, and personalized way. A+Bizz is the bridge your company needs to connect, measure, and optimize.

Discover how A+Bizz can make your operation smarter. Talk to us and schedule a demonstration.

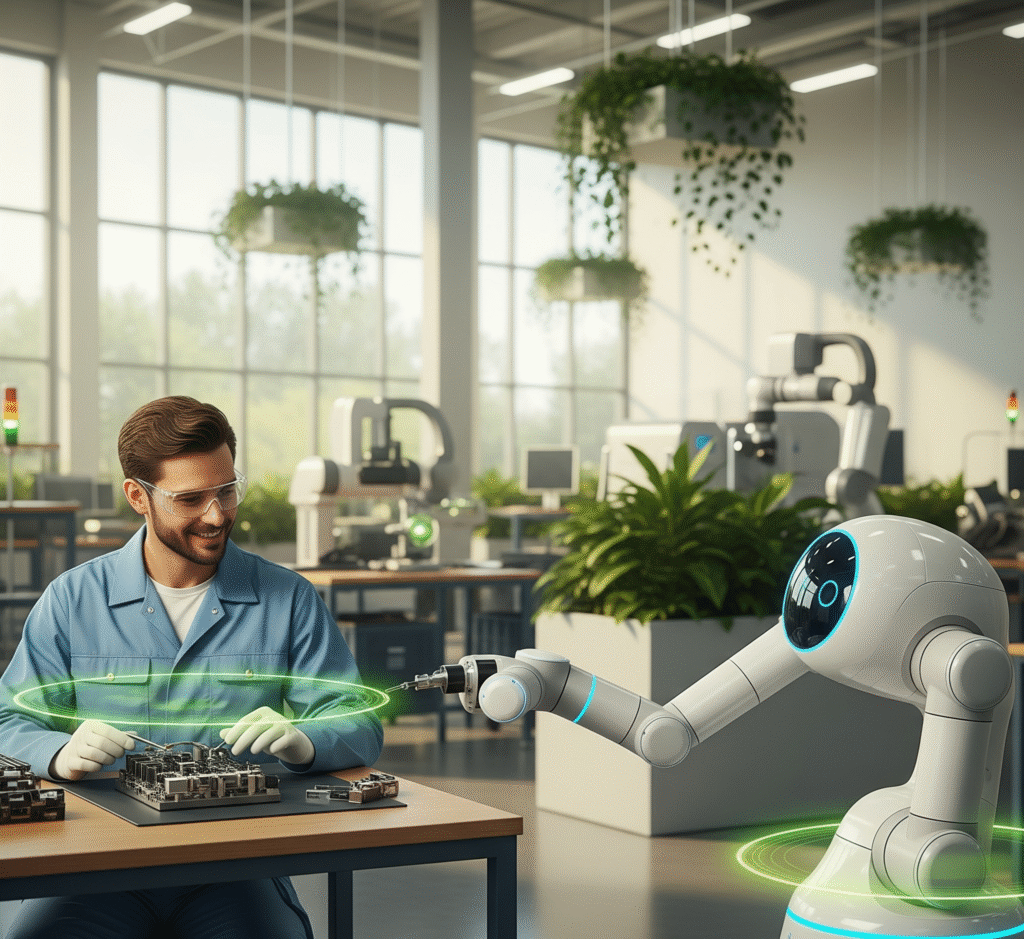

5.0: The Human, Sustainable, and Resilient Leap

If Industry 4.0 was about technology, Industry 5.0 is about purpose. It is a new phase that focuses on collaboration between humans and machines, where sustainability is no longer an option but a strategic pillar. Here, technology does not replace people but rather enhances their creative and problem-solving abilities.

In Industry 5.0, excellence is not just measured in profits but in:

- Sustainability: Measuring the carbon footprint of each manufactured product.

- Collaboration: Technology works in partnership with human beings.

- Resilience: Value chains that withstand shocks and interruptions.

Your company does not have to be left behind. A+Bizz is the bridge between Industry 4.0 and 5.0.

A+Bizz offers you a complete solution to reach this new level:

- Real-Time Monitoring: Measure consumption by sector in real time.

- True Cost Calculation: Use data and AI to estimate the real cost of each product.

- Detailed Reports: Calculate the environmental footprint of each manufactured product.

All with a quick installation, intelligent sensors, and a flexible, modular, and personalized logic for your SME.

Take the next step with A+Bizz. Find out how we can help your company evolve to the future of industry.